Références Construction navale

Crane ship "Saipem 7000"

Semisubmersible crane and pipelaying (J-Lay) DP vessel

Application information N° 101

Ballast tank application

Saipem 7000 was originally built as a semi-submersible crane vessel (Micoperi 7000) capable of lifting and installing offshore structures up to 14’000 tons in weight. In 1999 the vessel was converted to accom-modate a « J »-Lay Tower and pipe handling equipment for laying pipelines in deep water areas worldwide.

The tower is the largest in the world with a height of 135 meters, while the overall weight of the complete pipe laying facilities is 4’500 tonnes. The ballast tanks are fully controlled with 146 pcs. of stainless steel Trimod´Besta level switches.

Ballast System

Computer controlled system:

- 4 x 6’000 tons/h ballast pumps

- 40 ballast tanks with tot. 83’700 m³

- 14 rapid ballast tanks with tot. 26’000 m³

Classification

Lloyds Register and RINA

Compliance

NMD, HSE, USCG Rules

Trimod´Besta Ship register approvals

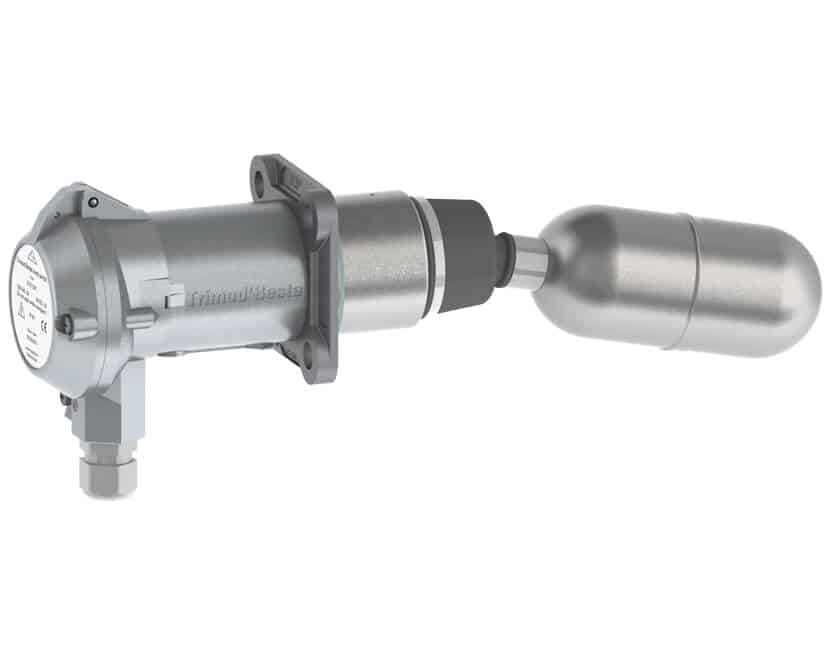

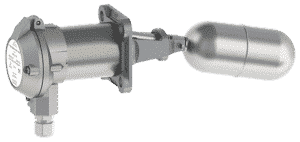

Installed level switch types

- 5A 01 04, stainless steel version

- 5U50A 01 041, stainless steel version, IP68 with 50m long cable

Marine Scrubber Systems

Application information N° 102

Application

Burning fossil fuel in ship diesel engines creates large amounts of toxic sulphur oxides (SOx) which are harmful to the world’s ecosystems. Not only the marine environment but also the human health can be seriously damaged for long term. For this reason, the ship owners are permanently called upon to meet the current regulations of the International Maritime Organization (IMO) which is appealing to the ship owners to reduce the output of SOx and triggers them to adapt their existing exhaust cleaning systems according to IMO’s latest rules. Due to the new scrubber technologies, the ship-owners have the possibility to run their fleets with cheaper heavy fuel oil while the output of toxic exhaust gases is reduced.

Trimod´BestaShip register approvals

Installed level switch types

- A 41C80 404

EN/DIN flange PN16 DN100

Hastelloy C Standard execution for operating temperatures up to 330°C.

- HA 41C80 404

EN/DIN flange PN16 DN100

Hastelloy C High temperature execution with heat exchanger for operating

temperatures up to 400°C.

.

.

Why Trimod´Besta?

Why Trimod´Besta?

Navy Industry

Application information N° 103

Application

Trimod´Besta level switches have been tested from NSWCCD Naval Surface Warfare Centre, Carderock Division for 36 months without failure on the USS Thomas S. Gates. As a result the US fleet has been equipped step by step with Trimod´Besta level switches.

Within the past years, we delivered several thousand level switches to the global industries (submarine, ship, air craft carrier).

Trimod´BestaShip register approvals

Installed level switch type

- A 011 051

Why Trimod´Besta?

Extract of a newspaper article

Submarine Industry

Application information: N° 104

Application

Since 1995 we have delivered a lot of Trimod´Besta level switches for the submarines of the Australian Navy.

The level switches control the interface level between sea water (density 1.017-1.030) and fuel (density 0.820-0.860) in the fuel thanks.

Collins Class

This submarine´s operational characteristics and range have been tailored specifically for its defence and two-ocean surveillance role in the Royal Australian Navy. Designed to be as quiet as advanced technology can achieve, Collins has been developed from five generations of submarines designed and built over the last 20 years for the Swedish Navy.

Trimod´BestaShip register approvals

Installed level switch type

- 5U2AE188 0118E188 408T1

Features:

- Submersible level switch IP68

- Special cable

- stainless steel housing, epoxy painted

-

Flange type 011, stainless steel, dry side epoxy painted and wet side in

Hastelloy C - Float module in Hastelloy C, suitable for interface control

Why Trimod´Besta?

Why Trimod´Besta?

Trimod´Besta level switches are designed for a life time of more than 30 years.

Références Pétrole et gaz

FPSO BW Pioneer in Gulf Of Mexiko, USA

Application information N° 201

Ex-proof Application

The BW Pioneer, a floating production storage and offloading (FPSO) vessel for the Gulf of Mexico is operated by BW Pioneer Ltd. an affiliate of BW Off-shore. The vessel is turret moored at a water depth of about 2600 meters – by far the deepest for an FPSO. The concept of Submerged Turret Loading (STL) is an anchored submerged buoy with an integrated turret. The mooring lines and the riser for the fluid transfer are connected to the turret within the STL buoy. The tanker is connected to the system by pulling the STL buoy into a mating recess in the bottom of the ship. When the STL buoy is locked to the tanker the vessel can freely weather wane without the aid of propulsion.

With its advanced safety features the ship withstands environmental loads from currents, waves and wind, connects to the buoy in waves up to 6 meters high and makes the process of offshore loading weather independent.

Trimod´Besta level switches are located in the BW Pioneer’s «connection room», which gets flooded while the ship connects to the buoy.

Requirement for level switches

- Flameproof design

- Hazardous area zone 1

- Wall mount in bilge well

- Operation in seawater

- Enclosure: IP68, submersed to 20m

- Relative air humidity 33% to 100% (tropical marine environment)

- Operating temperature To +17 to +45°C

Ex-Approval

EPS 09 ATEX 1238 X

Installed level switch types

- X5U40B8 01 04

Stainless steel switch, IP68 enclosure, flameproof housing,

40 meter cable and gold plated microswitch contacts.

Why Trimod´Besta?

Why Trimod´Besta?

The chosen explosion proof switches are certified acc. to EN 61079 and withstands very harsh conditions.

Luginetsky gas compressor station in Strezhevoy, Western Siberia, Russia

Application information N° 202

Ex-proof Application

Natural gas is highly pressurized as it travels through an interstate pipeline. To ensure that the natural gas flowing through any pipeline remains pressurized, compression of this natural gas is required periodi-cally along the pipe. This is accomplished by com-pressor stations, usually placed at 40 to 100 miles intervals

along the pipeline. The natural gas enters the compressor station where it is compressed by a turbine.

In addition to compressing natural gas, compressor stations also usually contain some type of liquid separators, much like the ones used to dehydrate natural gas during process. Usually, these separators consist of scrubbers and filters that capture any liquids or other undesirable particles from the natural gas in the

pipeline. Although natural gas in pipelines is considered ‹dry› gas, it is not uncommon for a certain amount of water and hydrocarbons to condense out of the gas stream while in transit. The liquid separators at compressor stations ensure that the natural gas in the pipeline is as pure as possible, and usually filters the

gas prior to compression.

Requirement for level switches

- Operating pressure po up to 100 bar

- Operating temperature To up to 380°C

- Explosion proof instruments

- Min. density: 0.4 kg/dm³

- All stainless steel version

Ex-Approval

PTB 03 ATEX 1006

Installed level switch types

- Z54K8 01 07

- Z54HK8 01 07

- Z54K8 135RY 032

- Z54HK8 011Z 76

standard square flange PN 25

standard square flange PN 25

ANSI 3”, cl. 900

standard round flange PN 25

.

.

Why Trimod´Besta?

Why Trimod´Besta?

Inert gas production on ships

Application information N° 203

Application

On tankers inert gas is being pumped into the cargo tanks during off-loading of flammable liquids. The inert gas controls the environment and prevents the formation of a combustible substance. It is produced on board the tankers by burning kerosene or exhaust gases inside an inert gas generator. Within the inert

gas generator, Trimod´Besta level switches are installed as high and low alarm switches in seawater tanks where soot particles and water soluble substances are washed out of the gas.

On FPSOs (floating production storage and offloading vessels) the inert gas generator is typically made of special steel 904L or SMO 254. In the application you see below, the Trimod´Besta level switch is installed into a customized stainless steel float chamber.

Conditions

- Ambient temperature and pressure (max. 0.15 bar)

- Saltwater spray

Installed level switch types

- level switches type A 01 041

- level switches type DB 01 04

- Test actuator type 2385 (option)

.

.

BP Bruce, North Sea 340 km NE of Aberdeen, Scotland

Application information N° 204

Bruce was discovered in June 1974 in acreage licensed to BHP in the 4th licensing round. Condensate, a light crude that exists as gas under reservoir conditions, was found 4000 metres below the seabed in a water depth of 121 metres. Further drilling was largely unsuccessful. However interest in the prospect was rekindled in early 1981 when BP discovered gas/condensate in an adjacent 5th round block in the centre, followed by a further discovery to the east by Total in 1984.

The transport system comprises a 6 km long, 32» diameter gas export pipeline that joins the 32» Total operated Frigg UK pipeline, taking gas to the St. Fergus Terminal. Further a 248 km long, 24» diameter oil export pipeline to the BP FPS unity platform and thence into the BP-operated Forties Pipeline System. The PUQ platform, (process / utilities / quarters) and D (drilling) platform are linked by a 47 metre bridge.

Requirement for level switches

- Operating pressure po up to 111 bar, ANSI cl. 900

- Operating temperature To -82°C up to +220°C

- Intrinsically safe circuits, gold plated contacts

- Density down to 0.58 kg/dm³

- Interface application 0.78 / 1.04 kg/dm³

Installed level switch types

Totally 83 Trimod´Besta units are installed.

- 5DBE28 131R 07

- 5DBE28 131R 08T1

- 5DBE28 132R 07

- 5DBE28 134RL 27

- 5DBE28 134RL 28T1

- 5DBE28 135JS 032

- 5TDB 131R 07

- 5TDB 141R 04G3

cl.150

cl. 150

cl. 300

cl. 600

cl. 600

cl. 900

cl. 150

cl. 150

low density 0.5 kg/dm³

interface control

low density 0.5 kg/dm³

low density 0.5 kg/dm³

interface control

low density 0.5 kg/dm³

low teperature appl.

low teperature appl.

All switches are fully in stainless steel and IP67. They are mounted in carbon steel, low temperature carbon steel and stainless

steel float chambers.

.

.

.

Why Trimod´Besta?

Why Trimod´Besta?

Références Pétrochimie & chimie

Fife Ethylene Plant in Mossmorran, Schottland

Application information N° 301

Ethylen cracker

ExxonMobil Chemical´s Fife Ethylene Plant (FEP) is one of

Europe´s largest and most modern ethylene plants. Construction

at Mossmorran, 25 miles north of Edinburgh, began in 1981 and

the plant was officially opened by the Queen in 1986. It was the

first plant specifically designed to use natural gas liquids from

the North Sea as feedstock.

The plant has an annual capacity of 830’000 tons of ethylene.

To make ethylene, ethane feedstock is heated to almost 900°C

to ‹crack› it to ethylene in the steam cracking furnaces. The gas

stream is then cooled to below -160°C to recover the valuable

ethylene product.

Requirement for level switches

- Hazardous area. Zone 0 for floats

- Intrinsically safe circuits, gold plated contacts

- Operating temperature To: -160°C to +320°C

- Min. Density: 0.4 kg/dm3

- Interface control of 2 liquids (e.g. oil and water)

- Extremely high reliability of switch mechanism

- Manufacturing of complex float chambers incl. welding procedure specification

Installed level switch types

Totally 114 Trimod´Besta level switches and 110 float chambers are installed in the hot (400°C) and in the cold (-160°C) part of the ethylene production process.

Switch types

(4 examples out of 21 different switches)

- 2B 131RE90 041

- 2DB 131RE91 07

- 2HB 134RE90 02

- 2TDB 132RLE91 76

.

.

Why Trimod´Besta?

Why Trimod´Besta?

References Production d'énergie

Ex-proof application in the power generation Co-Generation plant in Sydney, Australia

Application information N° 401

Ex-proof application

The photo on the front page shows a Co-Generation plant. Trimod´Besta level switches type ZKK5 01 04 are installed. They are used as low level alarm in the recycling process of the waste water cleaning.

The energy of the methane gas coming from the digesters powers large generators which in turn deliver the power for the plant itself.

Requirement for level switches

- Pressure: PN 25, max. 25 bar

- Operating temperature: -30 to 145°C

- Ambient temperature: acc. to EN 60079-0

- Density of the liquid: min. 0.7 kg/dm³

Installed level switch types

- ZKK5 01 04

Low / high power heaters, Eskom Hendrina power plant in South Africa

Application information N° 402

Applications

Trimod´Besta level switches mounted in float chambers are used in low power (LP) and high power (HP) heaters of the coal fired Eskom Hendrina Power Station in South Africa. This power station has ten 200 MW units with a total installed capacity of 2’000 MW.

Hendrina Power Station came into operation between June 1970 and December 1976. It is one of Eskom›s oldest operating power stations and the only one with 10 units.

When it was built, it had the longest turbine hall of any Eskom power station. Between 1995 and 1997 half of Hendrina’s 10 units were refurbished and now boast some of the most advanced system control technology in the world.

The station’s 5-in-1 control room was the first in the southern hemisphere.

Requirement for level switches

- Operating temp. up to 400°C

- Heat resistant flanges and float chambers

- Very dusty environment

Technical details

- Capacity: 2000 MW (10 x 200 MW units)

- Design efficiency at rated turbine MCR: 34.2%

- Ramp rate: 33.3% per hour

- Average availability over last 3 years: 88.8%

- Average production over last 3 years: 11‘718 GWh

Installed level switch types

The material of the float chambers is heat resistant carbon steel 15Mo3. The level switches are equipped with heat exchangers and partially with composites flanges made of heat resistant carbon steel 13CrMo44 or stainless steel.

- HAA 22C01 041

- HAA 01 041

.

.

Nuclear power station in Beznau, Switzerland

Application information N° 403

Plant information

The power plant is on an island formed by the course of the river and the channel for the Beznau hydro-electric power plant. Given the sufficient supply of cooling water from the Aare, there is no need for a cooling tower. Beznau consists of two near-identical units, Unit 1 and Unit 2. Their net output is 365 megawatts (MW) each. Both are baseload power plants, i.e. they generate

uniform electric power round the clock. They operate all the year round, except two to four weeks in summer, when the plants are shut down for their annual overhaul and replacement of their fuel rods.

Both units at Beznau nuclear power station are equipped with Westing-house pressurized water reactors. In these reactors, the water flowing through the reactor core is highly pressurized, so that it can not boil, despite the temperature of 312°C.

In the two steam generators, the heat generated in the reactor is released into a second circuit. Here, the water is completely sepa-rated from the first circuit and comes to the boil at lower pressure. The resultant steam is channelled on to the turbines which drive the generators.

Requirement for level switches

- Operating pressure po up to 70 bar, ANSI cl. 1500

- Operating temperature To max. 300°C

Installed level switch types

The power plant consists of about 100 level switches. The switches are used as high-, high high-, low- and low low-alarm and as safety relevant turbine trip. They are installed in the moisture separator reheaters, condensers, low- and high pressure preheaters, in feed-water tanks and as well in the Refuna heat

exchangers.

Refuna supplies heating from the Beznau nuclear power plant to around 15’000 residents of the region. Refuna makes an important contribution to a clean environment in this region.

- AA 01 04

- AA 01 051

- AA 21C 04

- AA 136JL 03

- P 01 04

- P 21C 04

- P 23E 02

PN 25

PN 25, protection bellow

EN/DIN PN 16

ANSI cl. 1500, ring joint

PN 25, pneumatic on/off

EN/DIN PN 16, pneumatic on/off

EN/DIN PN 63, pneumatic on/off

.

.

Références Construction de systèmes

Arroyito heavy water production plant in Argentina

Application information: N° 501

The plant

The Industrial Heavy Water Plant (PIAP), located at Arroyito (Province of Neuquén) is classified as a high-technology plant among conventional chemical industries. Its production capacity amounts to 200 tons per year and is split into two production lines of 100 tons each.

The process selected and applied by the PIAP for obtaining heavy water is based on a method known as «Monothermal Ammonia-Hydrogen Isotopic exchange».

The electromechanic equipment plus the structures weigh more than 27’000 tons and include, among others 250 heat exchangers, 240 pressure vessels, 90 gas compressors, 13 reactors, 30 distillation columns Additionally.

The PIAP contains two ammonia-synthesis reactors, each one of them with a production capacity of 2150 tons per day. These synthesis units are the largest in the world and are currently used in a closed circuit for obtaining virgin heavy water.

The technical characteristics of the synthesis reactors and the possibility of producing ammonia and fertilizers at an industrial scale, either individually or along with the production of heavy water, have generated appeal for both domestic and international investments in the Patagonian region.

Requirement for level switches

- Operating pressure po up to 261 bar (cl. 2500)

- Operating temperature To max. 221°C

- Intrinsically safe circuits for zone 1 and 2

- Gold plated microswitch contacts

- Float chamber: cold hydraulic pressure test at 420 bar

- Float chamber: helium leakage test

Float chamber test conditions

- Charpy-V at -30°C

- NDT test at -40°C (Pellini)

- All welding edges 100% PT

- Post weld heat treatments 620°C

- 100% PT test surface

- Cold hydraulic pressure test (cl. 2500: 420 bar)

- Helium leakage test

Installed level switch types

Bachofen has delivered 96 units of level switches and float

chambers.

- 42 x DB 132R 07

- 6 x HB 132R 07

- 32 x DB 136RS 032

- 16 x DB 137JS 032

ANSI cl. 300, To max. 80°C

ANSI cl. 300, To max. 221°C

ANSI cl. 1500, To max. 65°C

ANSI cl. 2500, To max. 120°C

Palm oil production in Malaysia

Application information N° 502

What is palm oil?

Palm oil and palm kernel oil is an important and versatile vegetable oil which is used as a raw material for both food and non-food industries. Obtained from the fruit (both the flesh and the kernel) of the oil palm tree, it contributes to the economic development of the producing countries and to the diets of millions of people around the world. Oil palms can grow 20 metres tall with leaves up to 5 metres long. They bear clusters of fruit all year long, with each fully matured cluster weighing up to 50 kg. Oil palms are highly efficient oil producers, with each fruit containing about 50% oil. As a result they require ten times less land than other oil-producing crops. Palm oil and palm kernel oil are entirely GM (Genetically modified) free. Vegetable oil production around the world totals over 144 million tones per year, of which over 47 million tones is palm oil. Along with soy oil, palm oil makes up 60% of world production. From the 1990s to the present time, the area under palm oil cultivation had increased by about 43%. Today, seventeen countries produce palm oil, though Malaysia and Indonesia account for 85% of global palm oil production, where 4.5 million people earn a living from palm oil. The top five producing nations are Indonesia, Malaysia, Thailand, Nigeria and Colombia.

Requirement for level switches

- Use in tank for collecting liquid fatty acid

- Pump control function with two switches

- Operating temperature To 150°C to max. 250°C

- Operating pressure po 2 mbar

- Microswitch with SPDT contact

Installed level switch types

- Standard version with square flange, Type: A 01 041

Pulp and Paper Industry

Application information N° 503

Pulp reactor plant application

Installed level switch types

- BB 31CE43 04H1E243

EN/DIN flange PN16 DN80 Hastelloy C

SIL2, SIL3 capable Standard execution for temperatures up to 150°C

- B 31CE43 04H1E243

EN/DIN flange PN16 DN80, Hastelloy C

SIL1, SIL3 capable Standard execution for temperatures up to 150°C

Why Trimod´Besta?

Why Trimod´Besta?

Easy handling of spare parts due to the three-modular switch design. The switching module can be replaced without interruption or dangerous opening of the reactor.

Other benefits include technical support in finding the right customer solution based on their installation plans. 3D computer models can also be supplied in case of secrecy.

Références Gestion des eaux

Vacuum waste collection system

application information N° 601

Application

A worldwide acting manufacturer of vacuum toilet and waste water treatment systems for ships and trains has used Trimod´Besta switches for more than 20 years. They use our level switches for a critical application in waste collecting tanks under vacuum conditions. Thousands of switches are on duty in

ships and trains around the globe.

Type A 01 051E15 is a standard level switch with a modified bellow assembly designed for use in sewage tanks under vacuum conditions.

The new vacuum tank unit heavy duty series is a vacuum tank solution for civil and military applications, in which the traditional method is enhanced by new pump technology. Energy consumption of the vacuum tank units is reduced by more than 50% compared to the competing technology. An extra vacuum reservoir and powerful pumps make complex new piping designs possible on large vessels even with only one vacuum generation unit. In vacuum tank units separate discharge pumps feed waste water mixing tanks in batches in combination with advanced treatment solutions. The tank units now require less maintenance, also because of the very robust Trimod´Besta level switches.

Requirement for level switches

- Low installation and no maintenance cost

- Black water tank with solid waste

- Vacuum condition

Installed level switch types

- A 01 051E15

E15: describes application specific modification